For medical cart power, it basically comes down to 4 choices:

- A big block battery fixed below with an On-Cart charger/inverter

- A smaller battery with a Hot swap back up battery – (1-20 minutes)

- Smaller low cost Hot Swap batteries with limited or no warranty

- Or a Professional multi battery Hot Swap system.

DCPower4C's Circadian and ProDurance systems effectively offer solution I, 2 and 4. but we would clearly argue that the most benefits essential to Hospital workflow and thus productivity improvement derive from the multi battery Hot Swap approach.

The big Li-Ion block battery idea was conceived as a solution for the failing SLA and NiMH blocks which were simply too heavy and too short lived. More recently Li-Iron (LIFE) versions have been supplied, these offer comparatively longer life. There are however significant downsides of a single block battery, this is both in Workflow consequences, technical terms and application terms.

- Downtime: On-Cart charging means that when the battery is empty, one cannot use the cart as intended for 3-5 hours. The cart is also per definition not mobile for 30-40% of the time. This is an unbridgeable 60-70 % efficiency level that has consequences. US feedback from Hospitals reported that up to 80% of carts are uncharged in the morning – because the evening staff forgot to plug in and/or the inverter emptied the battery.

- The Illusion of High Capacity is created because when new the block battery will pass through the demo phase and provide reassurance that the battery will last for ever! The reality is that the inverter use wastes about 25% of the capacity, the high quantity of cells in the pack cause balancing issues and rapid decline. The nurse will quickly need to adjust workflow to plugging in wherever possible.

- Repetitive Plugging in of carts involves lots of bending for the nurse ( back issues cost money), and involves cables hanging from Cart to socket in a corridor – legally a hazard in many countries.

- The Socket Workflow – the mobile application is now effectively furniture – located not for workflow optimization- at the Point of Care, but socket availability. Visitors to Hospitals frequently see the carts in the corridor, plugged in - the nurses must log-out to ensure that there is no unwanted access to the software - and thus re-log-in on next use - all very frustrating.

- Guarantied Time loss has huge negative Productivity implications: if nurses spend just 2% of their time walking to and from the cart over a cart life (7 years), the cost implications / waste are simply staggering.

- Double documentation instead of Point of care documentation increases the risk of error and thus significantly reduces patient safety.

- Nurse and Doctor Work satisfaction and thus compliance to the Digitalisation project are reduced due to frustration at time loss away from Point of Care. Patient satisfaction is also lowered.

- Narrow solution –like a 480Wh block – needs to fit all applications. This power level is OK for certain computer carts, but for a small laptop cart, Pad carts etc. it is massive overkill in terms of weight and cost. Conversly, it has too little capacity for a high level cart running all day. The system is not universal and cannot adapt to an application.

- The block battery with charger/inverter often adds significant weight to an already heavy cart for the nurse to push. (15 kg)

- When the battery nears the end of life the whole cart is put of action until maintenance has time to dismantle, test and replace the battery. This can be days to weeks extra downtime.

- Safety arguments are widely used – but the reality can be very different. Li-Iron batteries are Dangerous Goods and have caused major fires.

- Beware the warranties on these packs which are sometimes 5 or 10 years from the dealer, but not existent on the battery manufacturer site! Read the small print and capacity loss is often (some leading Brands) considered “wear and tear” and not covered. If a warrantied capacity level is not defined over a time period the warranty is meaningless, since old and totally useless Li-Ion/Iron batteries will still accept a charge and discharge after 10 years, but in practical terms are completely non-operational! Prorated warranties are expensive and cycle claims are for the dim witted – it is often shocking how a cycle can be defined!

- A further issue with the block battery is that the charging is normally governed by a simplistic algorithm – much like in your single cell mobile phone. These type of chargers do not prolong battery life, in fact they can devastate an otherwise reasonable battery performance. The Battery world knows that when it comes to happiness – it’s all about the charger!

- Finally we notice that most block battery carts are used with an inverter, taking the DC output and converting to AC. The AC output allows plugging in and the equipment then reconverts internally down to DC. The normal efficiency of the DC-AC conversion is around 80%. That means your new 480 Wh battery is reduced to 384Wh, and then another loss can be added for the reverse AC-DC conversion: this varies but assume a 5-15% loss. With 5% your new battery is then 364Wh. With the multiple low cost cells, and growing pack imbalance it’s rapidly down hill from there. So if you want to run a 40W load for 10 hours per day, your 480Wh purchase can’t do it!

But if you claim warranty, the standard test on the battery is without inverter and the warranty capacity level is set at 60% or 288Wh or not set at all!

So to conclude one can see that the benefits of using the block battery, just like their warranties are in reality severely limited in many cases.

The Multiple Battery Hot Swap system.

These type of systems address many of the pitfalls of the Block battery system, but be careful, to achieve long life cycles with smaller batteries is exceptionally challenging, thus the cells do need to be high performance and high quality, because the load handled by 100 cells as above is now shared by only 8 to 24 cells. The charging also requires more intelligence and accuracy which requires stable multi parameter control.

Technical Benefits:

- Hot Swap batteries are easy to replace, no long cart downtime whilst a new battery is installed. It is also easy to up capacity if new IT equipment is more demanding. Simply add a couple of batteries to the inventory

- Light weight means happy staff with less potential back issues

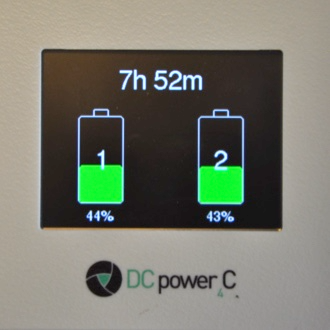

- No On-Cart charging required. A four battery system can have 2 on the cart, 2 on the charger. If both batteries are, as is so often the case, empty in the morning, snap on the two from the charger = no downtime.

- No On-Cart charging means total mobility, no safety issues with hanging cables, locating the nearest sockets, Carts blocking rooms or corridors whilst charging, and Nurses bending to plug in.

- No inverter, means no fan(s) less background noise and improved hygiene and thus less risk to patients.

Investment Benefits:

- Hot swap systems allow 100% Cart Uptime and full Mobility

- Full Mobility, means

- Documentation at the Point of Care

- Lower Error rate

- Improved medication logistics efficiency

- Improved Patient safety

- Improved Nurse/Doctor satisfaction and compliance

- Improved Patient experience

- Less time wasted on:

- Walking to and from cart

- Logging in and Out

- Bending/stretching to plug and unplug

- Higher Return on Investment – since the Digitalization projects aims to

- Improve Productivity

- Documentation at the Point of Care

There is no downside to Hot Swapping ........ if, and only if, cell pack quality is high.

Recent market trends are to purchase very low cost -laptop type - batteries, especially in All-In-One monitors. From a battery perspective we would argue these are almost certain to cause rapid failure and frustration, and more importantly will totally negate the benefits of mobile Digital documentation, essentially No productivity benefit will be achieved and in some cases there is a risk to safety.