The schematic below illustrates a power system that is designed to be completely modular, giving the customer options to match their application and workflow needs, but more importantly allowing the customer to up or down spec in future as the needs of the application evolve.

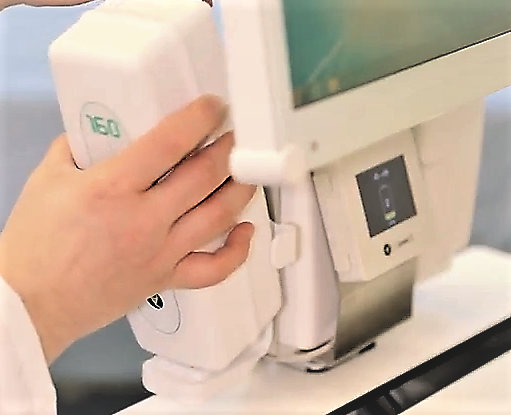

The flexibility starts with the batteries. Between 1 and 4 can be used. The capacities are currently 80, 160 or 200Wh. So your capacity choice on cart is effectively between 80 and 800Wh. The max load is also flexible depending on the mix you select. One battery can handle a 110W load. The standard system has a 150W load with a 175W max and can double up to 300W.

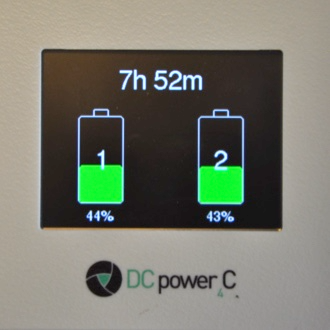

For planning purposes the ideal battery capacity for an IT cart would run all equipment at full use for 8 hours. One would then plan to have the same capacity off cart on the charger.

With a 30W cart load, one should have 240Wh battery power on cart, and 240Wh on the charger.

This would be a 4 x 160Wh system. The 2 batteries run well in excess of 8 hours, and need 4-5 hours to charge, this implies constant power. Our warranty gives a minimal 80% capacity after 3 years; at that point there is at least 256Wh on the cart, enough to last over 8 hours, allowing one to charge and cycle 24 hours for years to come. In reality this is an optimum, because your cart will never run at full power all day, and in all likelihood the two 160Wh batteries will cover a much longer period.

The flexibility of the Circadian system comes to its own as it ages or you change the load. Lets say the system is 3 years old and you significantly raise the load. You can add extra 160Wh batteries, or you can add 200Wh batteries, or indeed you can put the older batteries to use on a less demanding application while still using the same charger infrastructure. By attaching a Circadian mount you can power anything. Please note that C-mount versions with a direct double 5V USB out are available – ideal for a Pad cart with scanner.

However the most essential component is the Circadian Hot Swap module, which is designed to be upgradeable. The Battery input side can be varied but the flexible DC output side is what is really interesting.

The Circadian batteries output a voltage ranging from 16.6V down to 12.0V. The Hotswap module converts and regulates these to a 12/14V, 19V or 24V regulated output. 14V (12V) is the standard voltage for much equipment accepting power in the 18-11V range. Where such a range spec exists, the battery output range should sit within it in order to deliver 100% of its capacity. The 12V option is only for specific, usually older applications, the 14V output is ideal for most market inverters that are limited to max 15V. The 19V output covers the majority of laptops and monitors. 24V is common with scanners, label printers and some inverters. Where possible maximum power and thus run-time efficiency is achieved by such a DC to DC conversion. The Circadian Hot Swap 14V and 19V conversions are ultra-efficient losing only between 1% and 3% of capacity. Systems using DC-AC-DC are subject to 25-35% efficiency / capacity losses and should be avoided, if feasible. Why do suppliers still push inverter systems? It is to avoid complexity by plugging anything into one solution. However it is our contention that a better system design plan is rewarded with a massive efficiency boost that effects overall system reliability and life and thus Return on Investment and overall satisfaction.