Charger Flexibility and Benefits:

Currently the Circadian® system offers a multi-position On-Cart charger and a choice of 2 or 4 position chargers. DCPower4C does recommend that the 2 and 4 position chargers are used as the default system. With the low power draw on most carts, assuming correct capacity planning, there is absolutely no need to charge during shift, so that nurses do not need to plug in, locate carts next to electrical sockets, and can avoid the potential Health & Safety hazard (tripping) and damage (moving off whilst plugged in) presented by dangling plugged-in cables. With a Hot Swap system - ideally with the same quantity of batteries on the Cart as on the Charger, there is even no problem if the night shift forgot to charge! The On-Cart option has been made for extra flexibility but frankly because most Hospitals are now conditioned to expecting premature battery failure during the shift. This has lead to a sub-optimal nurse work flow with the cart located in the corridor next to the plug, which then has follow on effects on Nurse compliance to the Digital documentation requirement. The Cart was purchased for full mobility. The Circadian® system charge workflow solution reinstates this.

The On-Cart charge option uses a Power Supply which plugs into the Hot swap module and charges all batteries mounted on the cart simultaneously. The power supply is medical rated (2 x MOPP) to ensure safety and safe cleaning.

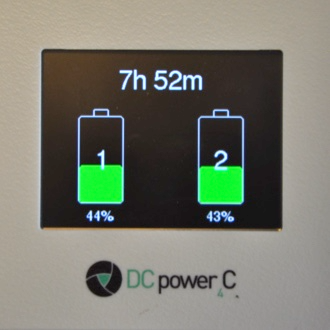

The 2 position charger is optionally desktop or Wall mounted, designed with a small base footprint. The 2 Circadian® batteries are dropped into the C-Mount cradles in an upright position. The battery LEDs light up and indicate charge status with 5 full LEDs indicating 100% full. The 4 position Chargers are wall mounted. These also use the drop in C-Mount cradles and on battery LEDs for charge status. Every hospital or market has different regulations, governing location; our advice is to locate the charger as near to the carts usage path as possible in order to optimize Nurse work flow. If, for example, there are 2 carts on a ward with 2 batteries on board each, ideally there would be a 4 position charger on a wall. The Nurse can simply wheel the cart to the charger and swap each battery. If the hospital has a corridor Hub system then a charger wall is feasible with multiples of the 4 position charger: 12, 16, 24 etc. charger positions. More can always be added, as a rule of thumb, max 10 chargers per electric socket are recommended. The chargers also use IEC 60601 compliant (2x MOPP) power supplies.

Fan Noise. One of the major irritations reported to DCPower4C was the constant back ground fan noise on the cart during patient consultations in the ward, or in the staff room. Other concerns were the dust distribution caused by fans in the direct patient environment. The Circadian® On-Cart charger is therefore fan-less. The 2 and 4 Position chargers - which are not positioned next to the patient - do have an inbuilt fan that is activated on usage or under high environmental temperatures. These fans fulfill low noise specs. Charger temperature management is highly efficient, as a result of using quality components combined with modern heat management algorithms.

Unlike most simple battery charge systems, where the charger dominates the process, the Circadian charging system is highly sophisticated and is completely controlled by the Circadian® battery itself. The battery determines the total charge by employing a range of algorithms to manage, temperature, current input, voltage levels and internal cell balance. All it needs is power input. Uniquely in this market segment it employs balancing algorithms to significantly prolong cell life and reduce potential imbalance /overcharge and over discharge issues.

Battery management systems.

The Circadian® batteries are smart and store a wealth of data. The 2 and 4 position chargers are manufactured with internal communication lines, ready for upgrade. An upgrade module will allow the hospital to convert each charger to a Battery management system with a memory and a WIFI or LAN output option. If this is implemented then the charger will communicate the key parameters and status of every battery charged on the system. A central server or web portal can pull all data and generate reports. The ability to tell the nurse where the closest full battery is located from a remote location will save busy IT staff considerable time each day.