Market Research: Hospital Feedback

The Circadian® system has been developed with the Hospital workflow in mind. The cost of ownership is a key factor, but more importantly it is essential to improve the daily experience of Nurses, IT technicians and maintenance staff in order to secure the Return on investment associated with going Digital. Hospital feedback regarding powering IT carts is loud and clear: they demand reliability, longevity, full mobility and flexibility, because the IT infrastructure evolves and easy battery management is essential to keeping costs down.

The surprise for us was the sheer scale of dissatisfaction with the Cart power experience; reliability was the first demand because most current systems are inherently unreliable. The nurses we spoke to in particular simply hate having to plug in carts, they don’t like the weight, the fan noise and the ever increasing instability of the system. The worst is starting the shift with an empty battery - apparently a common occurrence. Nurse compliance to the IT paperless regime is strained. In some major Hospitals it is so bad that the carts are now used to transport the paper patient records!

Why are there so many problems with power?

So what is the problem? We believe that the block battery under the cart concept is doomed to unreliability, increasing dissatisfaction and then failure. Initially the issue was the cell Chemistry, SLA or NiMH blocks are simply not conceived to handle daily full cycles for long periods. The weight of these systems is bordering unacceptable.

The answer seemed obvious, use High Capacity Li-Ion block batteries. And these do indeed represent an improvement. However there are a lot of choices when it comes to quality and price. The cells used are typically the small 18650 cells – consumer cells - and these range in bulk price from 2 to 15 USD depending on many parameters. To get a big block battery, 80-160 of these cells are typically needed. The Cart conundrum is then, that a good quality cell pack with a 100 cells may cost over 1000 USD without taking any other mark ups into consideration. Then add design, testing, margins, shipping, profit etc. and you are quickly at 4-5000 USD a price level that does not relate well to the old SLA batteries or indeed the Cart price. So many Cart suppliers have looked for the cheapest possible Li-Ion cell options and that’s where the unreliability and yes potential danger comes into the equation.

Cheap cells are made in the Far East in what is a competitive dog eat dog environment, many productions are not clean room, production tolerances are very lax and consistent cell quality is not a given. These cheap cells are prone to internal artefact (fire hazard) and when put together form imbalanced cell packs. An imbalanced cell pack declines rapidly and it at constant risk of overcharge (fire hazard). How it is acceptable that such cells now dominate in the cart battery market?

At DCP4C we believe that most suppliers are genuinely unaware of the above. They take a cell spec: it’s good for 3000 cycles and translate this to the cell pack life, whereas in fact, every battery specialist knows this is not going to happen. Just like with Laptops – using the same cells – the performance is down to 60% within a few years.

There is a second problem. Next to cheap comes easy. The block batteries are powered by a simplistic charger – no sophistication whatsoever, much like a mobile telephone charger. And then the inverter is added to get AC output. This is easy because the cart supplier just plugs the PC and Monitor etc. into a socket, which anyone can do. However the problem is that the setup is now DC to AC and back to DC. That first DC to AC conversion creates heat, thats why the annoying fan is running, but this heat loss is extremely inefficient. Typically 12-20% of the power is wasted. They reconvert back to the DC. This is equally loss making- assume 10–15%. So in total the easy step loses a whopping 22-35% of the battery capacity.

Look at that maths:

To run a 30W load for 12 hours per day without charging, the cart needs 360Wh. So take a 480Wh battery and you would think all is OK! The DC-AC-DC loss actually pulls down real available capacity to around 336WH. You are sub-optimal from day one. But All lithium ion batteries decline from day one onwards. Most typical consumer cells will be at 60% of capacity within 2 years if they are subjected to a full cycle. So your 480Wh is a 288Wh after two years- not including the conversion loss.

The next issue is charging. It has proven exceptionally difficult to implement a reliable charging regime at end of a nurse’s shift, because of the sheer complexity of the working schedules. The result is according to US research that in the morning typically 70-80% of carts are uncharged. The nurse has to plug in, the recharge takes 2-5 hours. So nurses need to plug in whenever, wherever they can, perversely the price is the loss of mobility, inconvenience and often delayed documentation.

For these reasons the block battery is simply not a viable solution for the intensive hospital workflow. Problems are system inherent. So whilst things have clearly improved in comparison to the SLA days, there is much plugging in and often minimal real use of the carts. This minimal use - just enough to keep the bosses happy- means the core benefits of the Digitalization program are not really harvested.

So what is the answer?

DCPower4C believes it is a 2 battery Hot Swap system and that the cells need to be of the highest quality, and not the cheapest. Many industries use Mission Critical cells, it is our contention that the IT Carts should be considered mission critical for 3 significant reasons:

- If the Digitalisation project works, there are huge potential Returns on investment for the clinic, that make the price level of the battery completely insignificant

- Successful Digitalisation is related to significantly improved patient outcomes and indeed a lower hospital death rate.

- Mission Critical cells are safe. With low cost Li-ion cell packs causing fires - google it! - why would a hospital accept such cheap cell pack on its wards?

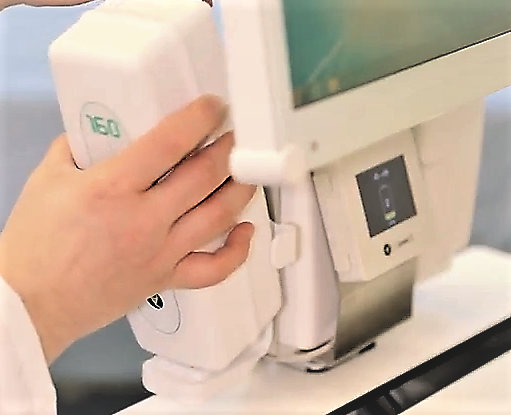

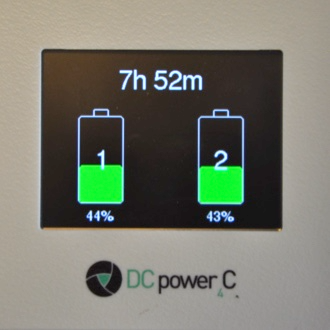

A Dual battery Hot Swap system will guarantee 24-7 run time, add in mission critical cells then the same batteries will run the cart for 5 years with no need to ever plug in the cart. Nurse compliance goes up- also due to the light weight of such systems - and the IT department has full flexibility to adapt the system with technical progress. Outcomes are improved and the safety hazard is reduced. If a DC-DC solution is included, then the cost efficiency of the system improves 20-30%.

This long term reliability actually gives a significantly higher return. This is the win-win scenario for IT carts.